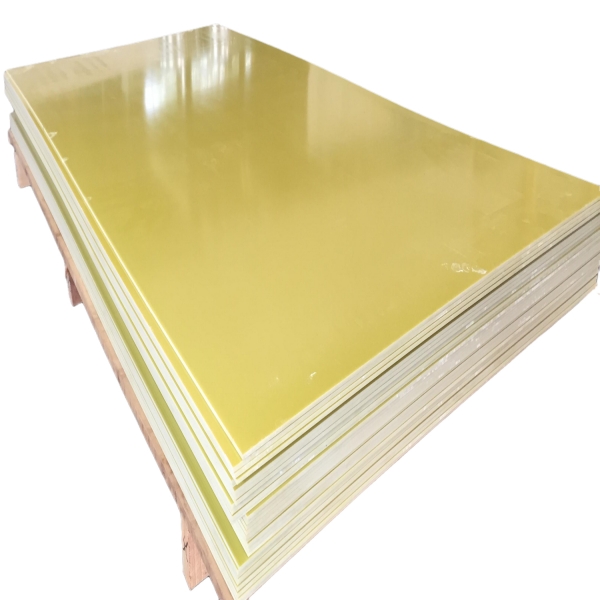

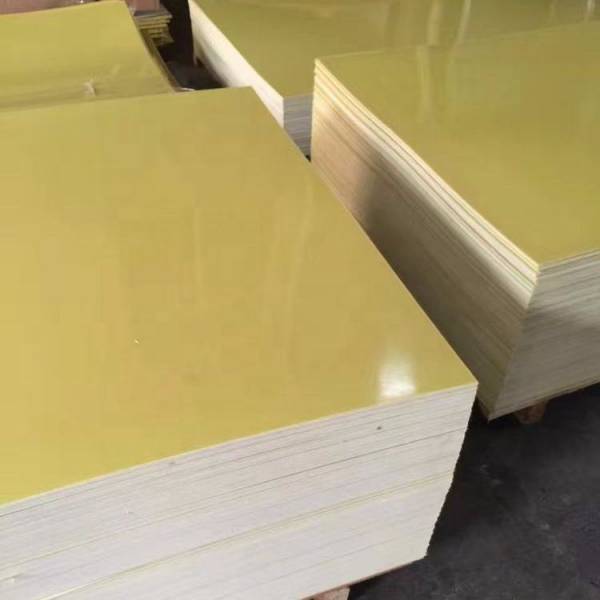

Takardar Laminated Mai Tauri ta Gilashin Epoxy Phenolic 3240

Bukatun Fasaha

1.1Bayyanar:saman zanen ya kamata ya zama lebur kuma santsi, babu kumfa, wrinkles ko tsagewa, kuma babu wasu ƙananan lahani kamar ƙaiƙayi, tarkace, da sauransu. Gefen zanen ya kamata ya kasance mai tsabta kuma babu ɓarna da tsagewa. Launin zai kasance iri ɗaya, amma an yarda da wasu tabo kaɗan.

1.2Girma da aka yardahaƙuri

1.2.1 Faɗi da Tsawon Takardu

| Faɗi & Tsawon (mm) | Juriya (mm) |

| >970~3000 | +/-25 |

1.2.2 Kauri da haƙurin da ba a san su ba

| Kauri na asali (mm) | Juriya (mm) | Kauri na asali (mm) | Juriya (mm) |

| 0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.12 +/-0.13 +/-0.16 +/-0.18 +/-0.20 +/-0.24 +/-0.28 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 80 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.95 +/- 2.10 +/-2.30 +/-2.45 +/- 2.50 +/- 2.80 |

| Bayani: Ga kauri mara suna wanda ba a lissafa a cikin wannan tebur ba, karkacewar za ta kasance iri ɗaya da ta kauri mafi girma na gaba. | |||

1.3Lanƙwasawa

| Kauri (mm) | Lanƙwasawa | |

| 1000mm (Tsawon mai mulki) (mm) | 500mm (Tsawon mai mulki) (mm) | |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 | ≤2.5 ≤2.0 ≤1.5 |

1.4Injin sarrafa aiki:zanen gado ba za su lalace ba, ko kuma ɓaraguwa idan aka yi amfani da injinan yanka, haƙa rami, kona bututu da niƙa.

1.5Sifofin jiki, na inji da na lantarki

| A'a. | Kadarorin | Naúrar | Matsakaicin ƙima | Matsakaicin ƙima |

| 1 | Yawan yawa | g/cm3 | 1.7~1.95 | 1.94 |

| 2 | Sha ruwa (shafi na 2mm) | mg | ≤20 | 5.7 |

| 3 | Ƙarfin lanƙwasa, daidai da laminations | MPa | ≥340 | 417 |

| 4 | Ƙarfin tasiri (Charpy, notch) | kJ/m2 | ≥30 | 50 |

| 5 | Ma'aunin watsawar Dielectric 50Hz | --- | ≤5.5 | 4.48 |

| 6 | Dielectric constant 50Hz | --- | ≤0.04 | 0.02 |

| 7 | Juriyar Rufi (Bayan awanni 24 a cikin ruwa) | Ω | ≥5.0 x108 | 4.9 x109 |

| 8 | Ƙarfin Dielectric, daidai da man transformer na laminationsin a 90℃+/-2℃, takardar 1mm | kV/mm | ≥14.2 | 16.8 |

| 9 | Wutar Lantarki Mai Rage Karfin Lantarki, daidai da man transformer na laminationsin a 90℃+/-2℃ | kV | ≥35 | 38 |

Shiryawa, Sufuri da Ajiya

Za a adana zanen gado a wurin da zafinsa bai wuce 40℃ ba, kuma a ajiye shi a kwance a kan farantin gado mai tsayin 50mm ko sama da haka. A ajiye shi nesa da wuta, zafi (na'urar dumama) da hasken rana kai tsaye. Tsawon lokacin adana zanen gado shine watanni 18 daga ranar da aka bar masana'anta. Idan tsawon lokacin ajiya ya wuce watanni 18, ana iya amfani da samfurin bayan an gwada shi don ya zama mai cancanta.

Bayani da Gargaɗi game da Amfani

Za a yi amfani da ƙaramin gudu da ƙaramin zurfin yanke g lokacin yin aiki saboda raunin tasirin zafi na zanen gado.

Yin amfani da injin da kuma yanke wannan samfurin zai fitar da ƙura da hayaki mai yawa. Ya kamata a ɗauki matakan da suka dace don tabbatar da cewa matakin ƙura yana cikin iyaka mai kyau yayin aiki. Ana ba da shawarar a yi amfani da iskar shaƙa ta gida da kuma amfani da abin rufe fuska na ƙura/ƙwaya.

Zane-zanen suna fuskantar danshi bayan an yi musu injin, ana ba da shawarar a shafa musu wani abu mai hana ruwa shiga.

Kayan Aikin Samarwa

Kunshin Ga Zane-zanen Laminated