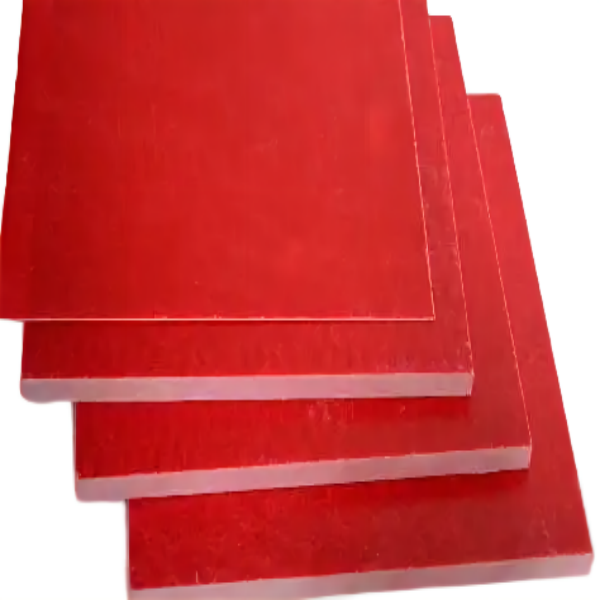

GPO-3 (UPGM203) Polyester Glass Mat Laminated Sheet mara saturated

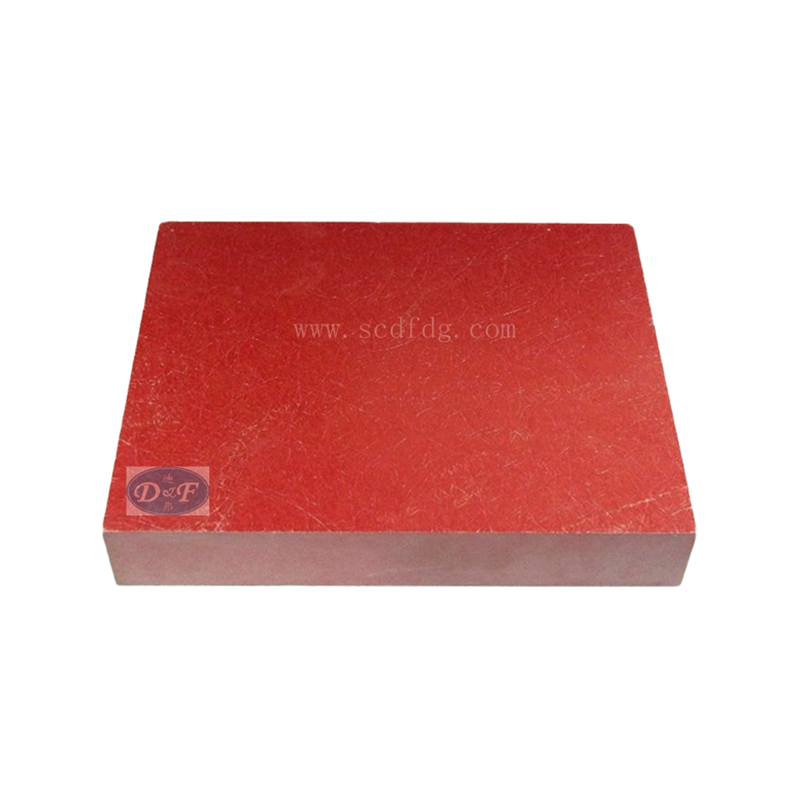

GPO-3 Molded Sheet (wanda kuma ake kira GPO3, UPGM203) ya ƙunshi tabarma marar gilashin alkali wanda aka cika kuma an haɗa shi tare da resin polyester mara kyau, kuma laminated ƙarƙashin babban zafin jiki da matsa lamba a cikin mold. Yana da machinability mai kyau, ƙarfin injiniya mai ƙarfi, kyawawan kaddarorin dielectric, kyakkyawan juriya na sa ido da juriya na baka. Yana tare da takaddun shaida na UL kuma ya wuce gwajin REACH da RoHS, da dai sauransu. Ana kuma kiransa da takardar GPO-3 ko GPO3, GPO-3 ko GPO3 insulation board.

Ana yin amfani da shi don yin tsarin rufi da kayan tallafi ko sassa a cikin injinan lantarki na F-class, masu canza wuta, kayan juyawa, masu watsewar kewayawa da kayan lantarki. Ana iya ƙera UPGM kai tsaye zuwa bayanan martaba daban-daban ko sassa na tsari.

Kewayon kauri2mm - 60mm

Girman takarda1020mm * 2010mm, 1000mm * 2000mm, 1220mm * 2440mm da sauran shawarwari kauri ko / da masu girma dabam

Babban launi: ja, fari ko wasu launukan shawarwari

Bayan UPGM laminated zanen gado, muna kuma samar da kuma samar da EPGM 203 zanen gado, da takardar size ne iri daya da na GPO-3. Launi shine rawaya ko kore. Don Allah a tuntube ni don ƙarin bayani.

Bukatun Fasaha

Bayyanar

Fuskokinta ya zama lebur da santsi, ba tare da blisters, wrinkles ko fasa ba kuma cikin hankali ba tare da wasu ƙananan kurakurai kamar su karce, haƙarƙari da launuka marasa daidaituwa ba.

Na al'ada thickness kumahaƙuri

| Nau'in Kauri (mm) | Haƙuri da aka yarda (mm) | Nau'in Kauri (mm) | Haƙuri da aka yarda (mm) | |

| 0.8 | +/-0.23 | 12 | +/- 0.90 | |

| 1.0 | +/-0.23 | 14 | +/- 1.00 | |

| 2.0 | +/- 0.30 | 16 | +/- 1.10 | |

| 3.0 | +/-0.35 | 20 | +/- 1.30 | |

| 4.0 | +/- 0.40 | 25 | +/- 1.40 | |

| 5.0 | +/-0.55 | 30 | +/- 1.45 | |

| 6.0 | +/-0.60 | 40 | +/- 1.55 | |

| 8.0 | +/-0.70 | 50 | +/- 1.75 | |

| 10.0 | +/- 0.80 | 60 | +/- 1.90 | |

| Lura: Don zanen gado na kauri mara ƙima da ba a jera su a cikin wannan tebur ba, karkacewar da aka yarda zai kasance daidai da na babban kauri na gaba. | ||||

Kaddarorin jiki, inji da lantarki

| Kayayyaki | Naúrar | Daidaitaccen darajar | Mahimman ƙima | Hanyar gwaji | ||

| Yawan yawa | g/cm3 | 1.65 ~ 1.95 | 1.8 | GB/T 1033.1-2008 | ||

| (Hanya A) | ||||||

| Ruwan sha, kauri 3mm | % | ≤ 0.2 | 0.16 | Saukewa: ASTM D790-03 | ||

| Ƙarfin sassauƙa, daidai gwargwado zuwa laminations (Mai tsayi) | A yanayin al'ada | MPa | ≥180 | 235 | Saukewa: ASTM D790-03 | |

| 130 ℃+/-2 ℃ | ≥ 100 | 144 | ||||

| Modules mai sassauƙa, daidai gwargwado zuwa laminations (Mai tsayi) | A yanayin al'ada | MPa | - | 1.43 x 104 | ||

| 130 ℃+/-2 ℃ | - | 1.10 x 104 | ||||

| Ƙarfin sassauƙa, daidai gwargwado zuwa laminations (Mai tsayi) | Mai tsayi | MPa | ≥170 | 243 | GB/T 1449-2005 | |

| Crosswise | ≥150 | 240 | ||||

| Ƙarfin Tasiri, daidai da laminations | KJ/m2 | ≥40 | 83.1 | GB/T 1043.1-2008 | ||

| (Charpy, ba a gani ba) | ||||||

| Ƙarfin Tasiri, daidai da laminations | J/m | - | 921 | Saukewa: ASTM D256-06 | ||

| (Izod, mai girma) | ||||||

| Ƙarfin ƙarfi | MPa | ≥150 | 165 | GB/T 1040.2-2006 | ||

| Matsakaicin elasticity na ƙwanƙwasa | MPa | 1.5x104 | 1.7 x 104 | |||

| Ƙarfin ɗaure, daidai da laminations | Mai tsayi | MPa | ≥55 | 165 | GB/T1447-2005 | |

| Crosswise | ≥55 | 168 | ||||

| Daidaitawa ga laminations | MPa | - | 230 | Saukewa: ASTM D695-10 | ||

| Ƙarfin matsi | ||||||

| Dielectric ƙarfi, perpendicular zuwa laminations (a cikin 25 # transformer mai a 90 ℃ +/-2 ℃, gajeren lokaci gwajin, Φ25mm / Φ75mm cylindrical lantarki) | KV/mm | ≥12 | 135 | IEC60243-1: 2013 | ||

| Breakdown irin ƙarfin lantarki, layi daya da lanimations (a cikin 25 # transformer mai a 90℃ +/-2℃, gajeren lokaci gwajin, Φ130mm / Φ130mm farantin lantarki) | KV | ≥35 | ?100 | |||

| Izinin dangi (1MHz) | - | 4.8 | 4.54 | GB/T 1409-2006 | ||

| Dielectric dissipation factor (1 MHz) | - | ≤ 0.03 | 1.49 x 10-2 | |||

| Arc Resistance | s | ≥180 | 187 | GB/T 1411-2002 | ||

| Juriya na bin diddigi | CTI | V | ≥ 600 | Farashin CTI600 | ||

| Ketare | GB/T 4207-2012 | |||||

| PTI | ≥ 600 | Farashin PTI600 | ||||

| Juriya na rufi | A yanayin al'ada | Ω | ≥1.0x1013 | 5.4 x 1014 | GB/T 10064-2006 | |

| (Taper pin electrodes) | Bayan 24h a cikin ruwa | ≥1.0x1012 | 2.5 x 1014 | |||

| Flammability (Hanya a tsaye) | Daraja | V-0 | V-0 | Farashin UL94-2013 | ||

| Waya mai haske | - | - | GWIT: 960/3.0 | GB/T5169.13-2006 | ||

| Barcol taurin | - | ≥ 55 | 60 | Saukewa: ASTM D2583-07 | ||

Dubawa, Alama, Marufi da Ajiya

1) Kowane batch ya kamata a gwada kafin a aika. Abubuwan dubawa don Gwaji na yau da kullun za su haɗa da Sashe na 2.1, 2.2, da Abu na 1 da Abu na 3 na Tebu 6 a cikin Sashe na 2.3. Abubuwan da ke cikin Sashe na 2.1, 2.2, yakamata a duba su ɗaya bayan ɗaya.

2) Za a adana zanen gado a wurin da zafin jiki bai wuce 40 ℃ ba, kuma a sanya shi a kwance akan farantin gado mai tsayi 50mm ko sama. Ka nisanta daga wuta, zafi (na'urar dumama) da hasken rana kai tsaye. Rayuwar ajiya na zanen gado shine watanni 18 daga ranar barin masana'anta. Idan lokacin ajiyar ya wuce watanni 18, ana iya amfani da samfurin kuma bayan an gwada shi don ya cancanta.

Bayani da Tsare-tsare don Gudanarwa da Amfani

1) Za a yi amfani da babban gudu da ƙananan zurfin yankan lokacin yin mashin ɗin saboda rashin ƙarfi na thermal watsin.

2) Machining da yanke wannan samfurin zai saki ƙura da hayaki mai yawa. Ya kamata a ɗauki matakan da suka dace don tabbatar da matakan ƙura suna cikin iyakokin da aka yarda yayin aiki. Ana ba da shawarar shaye-shaye na gida da amfani da ƙura / abin rufe fuska masu dacewa.

Takaddun shaida