Takardar rufewa ta D370 SMC da aka ƙera

Takardar rufewa ta D370 SMC nau'in takardar rufewa ce mai tsauri. An yi ta ne da SMC a cikin mold a ƙarƙashin zafi mai yawa da matsin lamba mai yawa. Tana da takardar shaidar UL kuma ta wuce gwajin REACH da RoHS, da sauransu. Ana kuma kiranta da takardar SMC, allon rufewa ta SMC, da sauransu.

SMC wani nau'in mahaɗin ƙera takarda ne wanda ya ƙunshi zare na gilashi wanda aka ƙarfafa da resin polyester mara cika, wanda aka cika da abin hana wuta da sauran abubuwan cikawa.

Takardun SMC suna da ƙarfin injiniya mafi girma, ƙarfin dielectric, juriya mai kyau ga harshen wuta, juriya mai bin diddigi, juriyar baka da ƙarfin juriya mai girma, haka kuma suna da ƙarancin shan ruwa, juriyar girma mai ƙarfi da ƙaramin lanƙwasawa. Ana amfani da takardun SMC don yin duk nau'ikan allunan rufi a cikin giyar makulli mai girma ko ƙasa. Hakanan ana iya amfani da shi don sarrafa sauran sassan tsarin rufi.

Kauri: 2.0mm ~ 60mm

Girman takardar: 580mm*850mm, 1000mm*2000mm, 1300mm*2000mm, 1500mm*2000mm ko wasu girma dabam dabam da aka yi shawarwari a kansu.

SMC

DMC

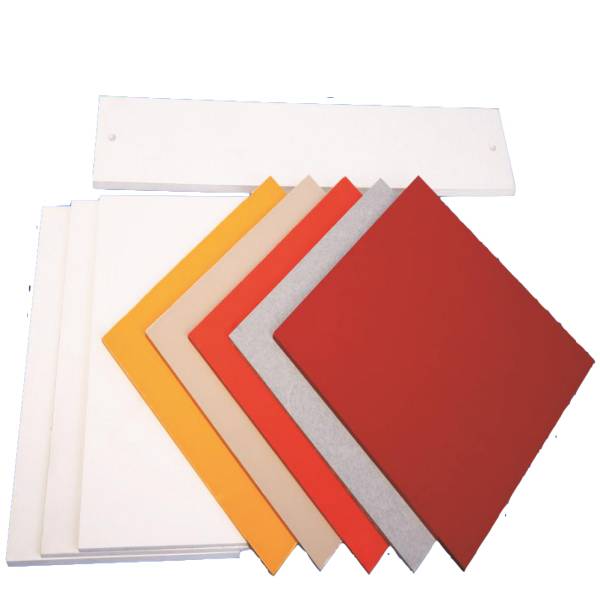

Takardun SMC Masu launi daban-daban

Takardun SMC

Bukatun Fasaha

Bayyanar

Ya kamata samansa ya kasance mai faɗi da santsi, ba shi da ƙuraje, tarkace da kuma lahani na injiniya. Ya kamata launin samansa ya zama iri ɗaya, ba shi da zare da aka fallasa. Ba shi da gurɓatawa, datti da ramuka masu bayyana. Ba shi da lalacewa da kuma tsagewa a gefunsa. Idan akwai lahani a saman samfurin, za a iya gyara su. Dole ne a tsaftace tokar da ta yi yawa.

bkarkacewa ta ƙarsheNaúrar: mm

| Takamaiman bayanai | Girman siffar | Kauri mara kauri S | Lanƙwasawa | Kauri mara kauri S | Lanƙwasawa | Kauri mara kauri S | Lanƙwasawa |

| Takardar D370 SMC | Tsawon dukkan bangarorin ≤500 | 3≤S<5 | ≤8 | 5≤S<10 | ≤5 | ≥10 | ≤4 |

| Tsawon kowane gefe | 3≤S<5 | ≤12 | 5≤S<10 | ≤8 | ≥10 | ≤6 | |

| 500 zuwa 1000 | |||||||

| Tsawon kowane gefe ≥1000 | 3≤S<5 | ≤20 | 5≤S<10 | ≤15 | ≥10 | ≤10 |

Bukatun aiki

Kayayyakin zahiri, na inji da na lantarki don zanen gado na SMC

| Kadarorin | Naúrar | Matsakaicin ƙima | Matsakaicin ƙima | Hanyar gwaji | ||

| Yawan yawa | g/cm3 | 1.65—1.95 | 1.79 | GB/T1033.1-2008 | ||

| Taurin Barcol | - | ≥ 55 | 60 | ASTM D2583-07 | ||

| Sha ruwa, kauri 3mm | % | ≤0.2 | 0.13 | GB/T1034-2008 | ||

| Ƙarfin lankwasawa, daidai da laminations | Tsawonsa | MPa | ≥170

| 243 | GB/T1449-2005 | |

| Giciye-giciye | ≥150 | 240 | ||||

| Ƙarfin Tasiri, daidai da laminations (Charpy, ba a san shi ba) | KJ/m2 | ≥60 | 165 | GB/T1447-2005 | ||

| Ƙarfin tauri | MPa | ≥55 | 143 | GB/T1447-2005 | ||

| Modulus ɗin elasticity mai ƙarfi | MPa | ≥9000 | 1.48 x 104 | |||

| Ƙuntatawa ta ƙera | % | - | 0.07 | ISO2577:2007 | ||

| Ƙarfin matsi (daidai da laminations) | MPa | ≥ 150 | 195 | GB/T1448-2005 | ||

| Modulus mai matsawa | MPa | - | 8300 | |||

| Zafin zafin da ke ƙarƙashin kaya (T)ff1.8) | ℃ | ≥190 | −240 | GB/T1634.2-2004 | ||

| Ma'aunin faɗaɗa zafin shafi (20℃--40℃) | 10-6/K | ≤18 | 16 | ISO11359-2-1999 | ||

| Ƙarfin wutar lantarki (a cikin man transfoma mai lamba 25# a 23℃+/-2℃, gwajin ɗan gajeren lokaci, Φ25mm/Φ75mm, lantarki mai siffar silinda) | KV/mm | ≥12 | 15.3 | GB/T1408.1-2006 | ||

| Ƙarfin wutar lantarki mai lalacewa (a layi ɗaya da laminations, a cikin man transfoma mai lamba 25# a 23℃+/-2℃, gwajin mataki-mataki na 20s, Φ130mm/Φ130mm, farantin lantarki) | KV | ≥25 | >100 | GB/T1408.1-2006 | ||

| Juriyar girma | Ω.m | ≥1.0 x 1012 | 3.9 x 1012 | GB/T1408.1-2006 | ||

| Juriyar saman | Ω | ≥1.0 x 1012 | 2.6 x 1012 | |||

| Izini na dangi (1MHz) | - | ≤ 4.8 | 4.54 | GB/T1409-2006 | ||

| Ma'aunin watsawar Dielectric (1MHz) | - | ≤ 0.06 | 9.05 x 10-3 | |||

| Juriyar Baka | s | ≥180 | 181 | GB/T1411-2002 | ||

| Juriyar Bin-sawu | CTI

| V | ≥600 | 600 Wuce gona da iri | GB/T1411-2002

| |

| PTI | ≥600 | 600 | ||||

| Juriyar rufi | A yanayin da ya dace | Ω | ≥1.0 x 1013 | 3.0 x 1014 | GB/T10064-2006 | |

| Bayan awanni 24 a cikin ruwa | ≥1.0 x 1012 | 2.5 x 1013 | ||||

| Rashin ƙonewa | Matsayi | V-0 | V-0 | UL94-2010 | ||

| Ma'aunin iskar oxygen | ℃ | ≥ 22 | 32.1 | GB/T2406.1 | ||

| Gwajin waya mai haske | ℃ | −850 | 960 | IEC61800-5-1 | ||

Jure ƙarfin lantarki

| Kauri mara iyaka (mm) | 3 | 4 | 5~6 | >6 |

| Jure wa ƙarfin lantarki a cikin iska na minti 1 KV | ≥25 | ≥33 | ≥42 | >48 |

Dubawa, Alama, Marufi da Ajiya

1. Ya kamata a gwada kowace batch kafin a aika.

2. Dangane da buƙatun abokan ciniki, hanyar gwajin juriyar ƙarfin lantarki ana iya yin shawarwari bisa ga zanen gado ko siffofi.

3. An lulluɓe shi da akwatin kwali a kan fakiti. Nauyinsa bai wuce kilogiram 500 a kowace fakiti ba.

4. Za a adana zanen gado a wurin da zafin jiki bai wuce 40℃ ba, kuma a ajiye shi a kwance a kan farantin gado mai tsayin 50mm ko sama da haka. A ajiye shi nesa da wuta, zafi (na'urar dumama) da hasken rana kai tsaye. Tsawon lokacin adana zanen gado shine watanni 18 daga ranar da aka bar masana'anta. Idan tsawon lokacin ajiya ya wuce watanni 18, ana iya amfani da samfurin bayan an gwada shi don a tabbatar da cancantarsa.

5. Wasu kuma za su bi ƙa'idodin GB/T1305-1985,Ka'idoji na gabaɗaya don dubawa, alamomi, marufi, jigilar kaya da adana kayan thermosetting na rufi.

Takardar shaida