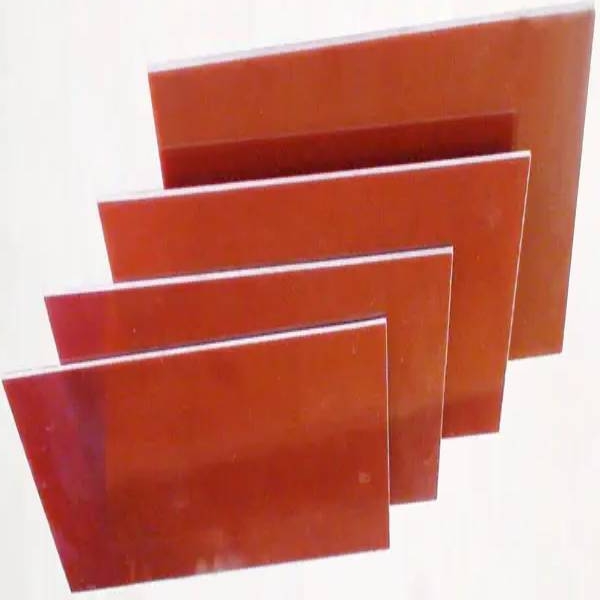

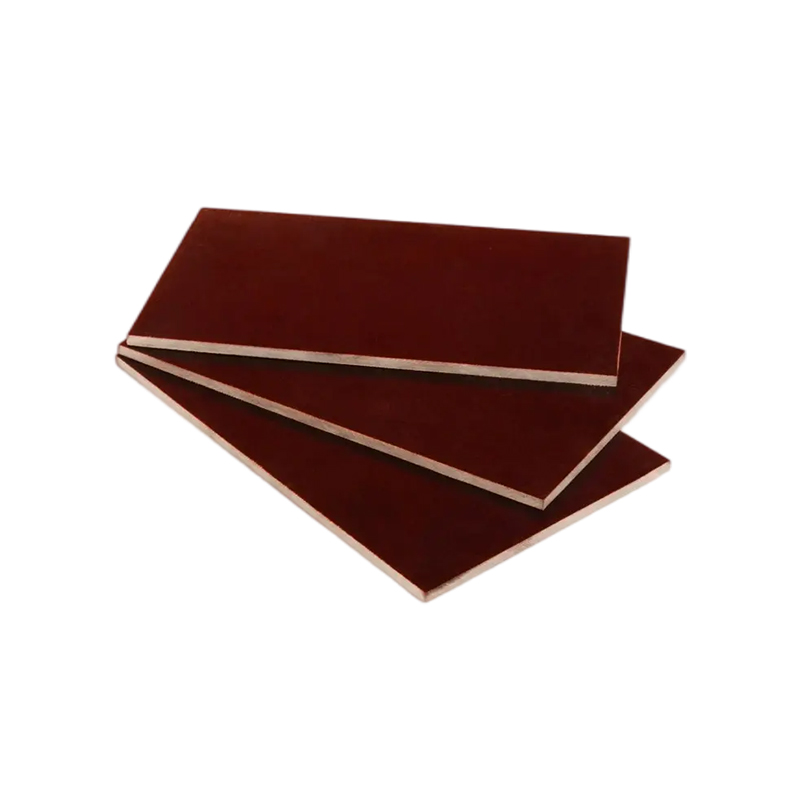

Zane Mai Rufi Mai Laminated na Gilashin PIGC301 Polyimide

DF205 Canza Gilashin Melamine Zane Mai Tauri Laminated Sheetya ƙunshi zane mai gilashi da aka saka wanda aka sanya masa ruwa kuma aka haɗa shi da resin thermosetting na melamine, wanda aka lakafta a ƙarƙashin zafi mai yawa da matsin lamba mai yawa. Yadin gilashin da aka saka bai kamata ya yi amfani da alkali ba.

Tare da babban ƙarfin injiniya da dielectric da kuma kyakkyawan juriya ga baka, an yi nufin takardar don kayan lantarki a matsayin sassan tsarin kariya, inda ake buƙatar juriya mai ƙarfi. Hakanan ya wuce gano abubuwa masu guba da haɗari (Rahoton RoHS). Yayi daidai da takardar NEMA G5,MFGC201, Hgw2272.

Kauri da ake da shi:0.5mm~100mm

Girman takardar da ake da shi:

1500mm*3000mm,1220mm*3000mm,1020mm*2040mm,1220mm*2440mm,1000mm*2000mm da sauran girma dabam dabam da aka yi shawarwari a kansu.

Kauri da Juriya na Nominal

| Kauri mara kauri, mm | Karkacewa, ±mm | Kauri mara kauri, mm | Karkacewa, ±mm |

| 0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | 0.12 0.13 0.16 0.18 0.20 0.24 0.28 0.33 0.37 0.45 0.52 0.60 0.72 | 10.0 12.0 14.0 16.0 20.0 25.0 30.0 35.0 40.0 45.0 50.0 60.0 80.0 | 0.82 0.94 1.02 1.12 1.30 1.50 1.70 1.95 2.10 2.30 2.45 2.50 2.80 |

| Lura:Ga zanen gado mai kauri mara suna wanda ba a lissafa a cikin wannan Tebur ba, karkacewar za ta kasance iri ɗaya da ta babban kauri na gaba | |||

Ayyukan Jiki, Inji da Dielectric

| A'a. | Kadarorin | Naúrar | darajar | |

| 1 | Ƙarfin lankwasawa, daidai da laminations | A zafin ɗaki. | MPa | ≥400 |

| A 180℃±5℃ | ≥280 | |||

| 2 | Ƙarfin tasiri, Charpy, Notch | kJ/m2 | ≥50 | |

| 3 | Jure wa ƙarfin lantarki, a tsaye zuwa laminations, a cikin man transformer, a 90±2℃, minti 1 | kV | Duba teburin da ke ƙasa | |

| 4 | Jure wa ƙarfin lantarki, a layi ɗaya da laminations, a cikin man transformer, a 90±2℃, minti 1 | kV | ≥35 | |

| 5 | Juriyar rufi, a layi ɗaya da laminations, bayan nutsewa | Ω | ≥1.0 × 108 | |

| 6 | Ma'aunin watsawar Dielectric 1MHz, bayan nutsewa | — | ≤0.03 | |

| 7 | Izinin dangi, 1MHz, bayan nutsewa | — | ≤5.5 | |

| 8 | Sha ruwa | mg | Duba teburin da ke ƙasa | |

| 9 | Rashin ƙonewa | rarrabuwa | ≥BH2 | |

| 10 | Rayuwar zafi, ma'aunin zafin jiki: TI | — | ≥180 | |

Jure wa ƙarfin lantarki, daidai da Lamination

| Kauri, mm | Darajar, KV | Kauri, mm | Darajar, KV |

| 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 | 9.0 11 12 13 14 16 18 20 22 | 1.8 2.0 2.2 2.4 2.5 2.6 2.8 Sama da 3.0

| 24 26 28 29 29 29 29 31

|

| Lura:Kauri da aka lissafa a sama shine matsakaicin sakamakon gwaji. Za a sami takaddun da kauri tsakanin matsakaicin kauri guda biyu da aka lissafa a sama, ƙarfin juriya (daidai da laminations) ta hanyar Interpolation Method. Takardu sun fi siriri fiye da 0.5mm, ƙimar ƙarfin juriya ya zama iri ɗaya da takardar 0.5mm. Za a yi amfani da zanen da ya fi kauri fiye da 3mm zuwa 3mm a saman ɗaya kafin gwaji. | |||

Shan Ruwa

| Kauri, mm | Darajar, mg | Kauri, mm | Darajar, mg |

| 0.5 0.6 0.8 1.0 1.2 1.5 2.0 2.5 3.0 4.0 | ≤25 ≤26 ≤27 ≤28 ≤29 ≤30 ≤32 ≤35 ≤36 ≤40 | 5.0 6.0 8.0 10.0 12.0 14.0 16.0 20.0 25.0 22.5 (na'ura, gefe ɗaya) | ≤45 ≤50 ≤60 ≤70 ≤80 ≤90 ≤100 ≤120 ≤140 ≤150 |

| Lura:Kauri da aka lissafa a sama shine matsakaicin sakamakon gwaji. Za a samo takardu masu kauri tsakanin kauri biyu da aka lissafa a sama, shanyewar ruwa ta hanyar Interpolation.Hanyar.Takardu masu sirara fiye da 0.5mm, ƙimar za ta yi daidai da takardu masu kauri fiye da 25mm. Takardu masu kauri fiye da 22.5mm za a yi musu injin ƙera su zuwa 22.5mm a kan wani wuri kafin a yi gwaji. | |||

Shiryawa da Ajiya

Za a adana zanen gado a wurin da zafin jiki bai wuce 40°C ba, kuma a sanya shi daidai a kan kushin da tsayinsa ya kai 50mm ko sama da haka.

A ajiye a nesa da wuta, zafi (na'urar dumama) da hasken rana. Tsawon lokacin adana zanen gado shine watanni 18 daga ranar da aka aika. Idan tsawon lokacin ajiya ya wuce watanni 18, ana iya amfani da samfurin muddin an gwada shi don ya cancanta.

Bayani da Kariya don Amfani da Shi

Za a yi amfani da babban gudu da ƙaramin zurfin yankewa yayin yin injin saboda raunin tasirin zafi na zanen gado.

Yin amfani da injina da yanke wannan samfurin zai fitar da ƙura da hayaƙi mai yawa.

Ya kamata a ɗauki matakan da suka dace don tabbatar da cewa matakin ƙura yana cikin iyaka mai kyau yayin aiki. Ana ba da shawarar a yi amfani da abin rufe fuska na ƙura/ƙwaya mai kyau.

Kayan Aikin Samarwa

Kunshin don zanen gado mai laminated